Manufacturing FIBC Big Bag Raw Materials- Fabric Two

Multi-function FIBC Big Bag Fabric Cutting Machine

Model BigbagCUT

When there are requirements for the cutting blemish of fabric in FIBC big bags and the fabric surface can not be free of dyes and impurities, the above problems may occur in traditional manually cut fabric (cloth), so the design of FIBC big bag fabric cutting machine can be avoided relatively. For different kinds of raw materials ( rolls of tubular fabrics or rolls of flat fabrics ), under the link of cutting plant, if diversified cutting types and sizes are needed, it will be more suitable to choose a multifunctional automatic FIBC big bag fabric cutting machine. Certainly, the following factors need to be considered in the proportion and selection of one or more multifunctional FIBC big bag fabric cutting machines:

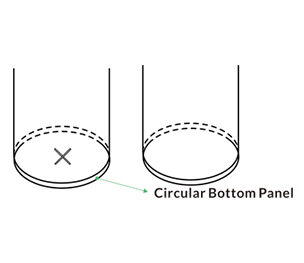

The overall equipment placement position of the cutting plant; The space proportion of machines; The ratio of personnel; Multi-functional FIBC big bag fabric cutting machines adopt platform structure, which is modular as a whole, so it needs professional skilled workers to install and debug it; The overall environment of the plant ( temperature, humidity, safety level requirements); The overall operation and management of the plant ( The differentiation of small, medium and large-scale enterprise also needs to consider one of the significant factors in choosing multifunctional FIBC big bag fabric cutting machine ); Besides, choosing the equipment proportion of multifunctional automatic fabric cutting machines also need to be combined with the machines proportion of FIBC printing press machines in the next process; For the diversification of fibc big bag types of final export products, including ( standard square FIBC big bags with filling and discharging spouts, circular (round) FIBC big bags with F/S and D/S,etc.), so it is relatively suitable to select multi-function automatic fabric cutting machines; As other aspect- raw materials, for raw material enterprises with self-production ability, after receiving the order, the previous manufacturing process should also be considered for the cutting plant, such as the FIBC big bag fabric technical style and output required for tape stretching, circular loom link, so as to judge wheter it is suitable to choose a multi-funtion automatic fabric cutting machine.

Multifunctional Modulars of Model BigbagCUT

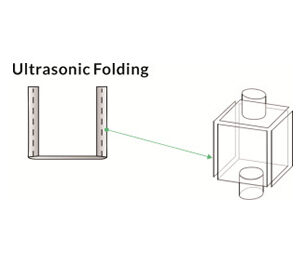

The multi-function automatic FIBC big bag fabric cutting machine can also add ultrasonic devices on both sides to complete the folding welding on both sides of the fabric estabilishing a foundation for entering the FIBC big bag sewing process; The ultrasonic patterns roller can be replaced or customized as based on the needs of specific patterns roller. Ultrasonic embossing adopts frequency broadband tracking technology, so that the output frequency of the ultrasonic generator can always be consistent with the frequency of the transducer, thus ensuring the quality of sewing and embossing, which is effectively prolonging the life of the ultrasonic generator and transducer device.

The FIBC big bag fabric of unwinding roll can choose air cylinder with lifting or without lifting. According to actual situation ( the weight of self-purchased or self-manufacturing roll), the overweight fabric roll can be lifted with air cylinder when it is coiled, which can increase its stability and accuracy. The ratio of personnel in this link is small, considering the convenience, which can also choose air cylinder lifting to complete it.

Multi-function FIBC Big Bag Fabric Cutting Machine

This machines by servo control systems so that can achieve relatively accurately drag the plastic woven fabric.

Multi-function FIBC Big Bag Fabric Cutting Machine

The plastic woven fabric works at the cutting knife of mold and transverse cutting to cut length under the multifunctional modules, finally it can form woven fabric in FIBC big bags with different technological requirements.