Automatic FIBC Big Bag Cutting Machine

SimpleCUT

Model

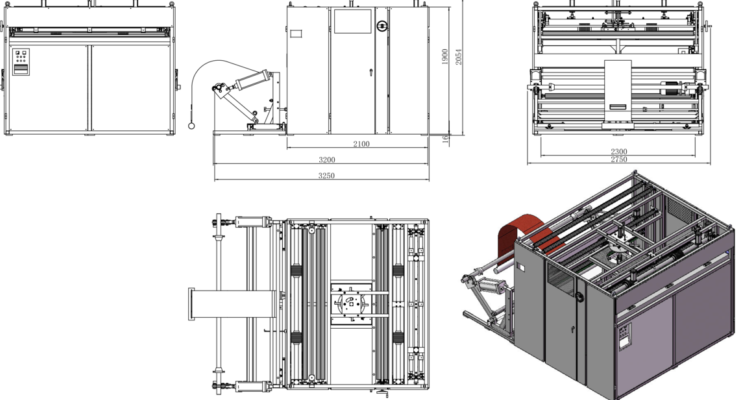

Considering the composition of the container bag body (the maximum width of the tubular fabric and flat fabric for ), we designed two width series, 2250 and 1400.

Our Fabric Cutting machines are available under three machine models: SimpleCUT, BigBagCUT and StarbaseCUT.

- The Model SimpleCUT is compactness, which box-like structure makes full use of space to set up necessary workstations.

It is an ideal choice for customers without special bag type processrequirements.

- This Fabric Cutting Machine can be transported as a complete set, without installation and debugging, making it easy to operate.

Advanced new cutting system, output could be reach 30 pcs/min.

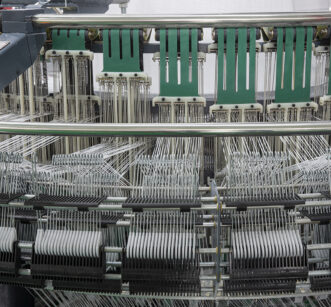

● Machine 1,400 for Flat Fabric

● Machine 2,250 for Tubular Fabric

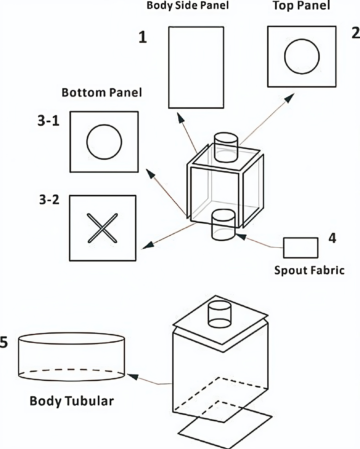

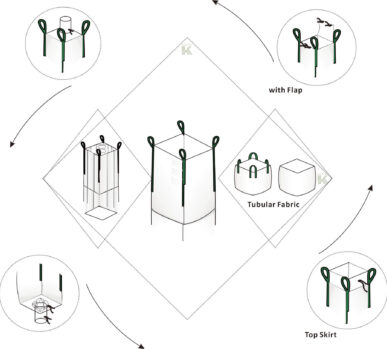

#1 Body Side Panel

#2 Top Spout Panel (O holing)

3-1/3-2 Bottom Spout Panel (O and X holing)

#4 Spout Fabric

#5 Body Tubular (2,250 model only)

Include

Features of Automatic Big Bag Cutting Machine

Model Different Table

SimpleCUT-1400

SimpleCUT-2250

Option List

– Automatic Big Bag Cutting Machine

Model SimpleCUT – Automatic FIBC Big Bag Cutting Machine

READY-USE Delivery Machine

Built-in Control Panel

Energy Efficiency Design