Big Bag Film Blowing Machine

Materials are including LLDPE, LDPE, HDPE, MLLDPE, EVA.

The single layer film blown is used in liner bag of woven bag; the three layers film blown is used in liner bag of FIBC big bag. These application: agricultural,etc.

Working Environment:

• Power Supply: 380(400) V/ 50Hz /3-phase AC + TN-C-S

• Compressed Air: 0.8Mpa

• Instrument Air: 0.8Mpa

• Temperature Range: +15 to + 40℃

• Relative Air Humidity: max.75% at reference temperature +35℃

• The Recycle Cooling Water, Temperature: ≤20℃ : about 60m³ ≥0.3Mpa

Models | FilmBlow-W-1-1000 ( Single Layer ) | FilmBlow-F-3-2500 ( Three Layers ) |

|---|---|---|

Screw Dia | Φ55mm | Φ65mm; Φ75mm; Φ65mm |

Film Lay-Flat Width | 300-1,000mm | 1,500-2,200mm |

Ratio of L/D | 32:1 | 30:1 |

Max.Screw Revolution | 120rpm | 110rpm |

Max.Extrusion Output | 120kg/hr | 500kg/hr |

Output | 40-90kg/hr, depending on resin and products dimensions | 250-350kg/hr, depending on resin and products dimensions |

Film Thickness | 0.01-0.06mm ( PE ) | 0.04-0.15mm |

Dimension | 70,000 x 3,500 x 6,000mm | 13,500×8,500×12,500mm |

• Heating Method: Ceramic Heating, Stainless Steel Cover

• Cooling Type: Fan Automatic Subsection (3 Sections) Cooling; Precise Temperature Control

• Barrel Cooling Blower Power: 240W×3sets ( single layer )

• Type: Spiral Mandrel

• Material: 40Cr Made of alloy steel

• Heating Method: Ceramic Heating(Heating is more uniform and cooling is faster).

High precision,good finish and no deformation.

• Air Ring Dia: φ1,000 mm

• Blower Power: 5.5 Kw, Frequency Control

• Motor Power: 3 Kw

• Max. Film Width: 2,400 mm

• Max. Dia of Film Roller: 700 mm

• Winding Shaft: Φ300×2,400 mm; 2400 mm-working pressure 4-5 kg

The shaft heads on both sides of the winding roller are all treated with anti-rust treatment.

Mainly Consisting of System

Mainly consisting of system is also included that “auto loader” “screen changer”.

Optional System Parts:

• IBC system

This system not only can rapidly cooling bubble, exhaust inner heat, water molecules and emissions of bubble,but also can supply new cooling air , lower the inner temperature of the bubble, increase the output and improve the mechanical properties of films.

• Take off Unit with Rotary System Unit

Haul-off Tower : Column adopts 140 mm*140 mm square tube, height 6 m, 2 floors platform, guardrail height 1.1 m;

Haul-off Speed : Max 60 m/min

Roller Length : 1,100 mm

Roller Material:Synthetic rubber

The film rotating device are moving relatively to the bubble at the speed of 0. 1 – 0. 3r / min for ± 360 °, so that the thickness deviation caused by die, the air ring and the tower frame is distributed at random, which ensures that the high-quality film are rolled at the winder.

• EPC System

Correct the film.

Three Layers FIBC Blown Film Machine

• Extruder

Barrel Cooling Blowers: 370 w x 4 sets / 370 w x 5 sets; / 370 w x 4 sets;

Extrusion Output: Φ65 125 kg, Φ75 150 kg, Φ65 125 kg;

Heating Zones: Φ65 4 zones, Φ75 4 zones, Φ65 4 zones;

Main Motors: Φ65 37 Kw, Φ75 55 Kw, Φ65 37 Kw, Frequency Control;

• Die

Diameter: Ф550 mm; Cold Steate Die Clearance: 2.4 mm;

• Non-Stop Winder

2 Station Non-stop Winder; Motor Power: 3 Kw; Max. Winding Speed: 80 mtr./min;

Max. Film Width: 2,400 mm; Max. Dia. of Film Roller: 700 mm; Winding Shaft: Φ300×2,400 mm;

Air Shaft Dia.: Φ76mm; Splitting Cutter; Air Shaft Forklift

• Precision Type Dual Duct Air Ring

• Electrical Control System

Heavy duty air expansion reeled heating control cabinet and electrical operating cabinet by full ventilation and heat dissipation device;

Equipment safety labels are complete; Control cabinet equipment alarm device;

• Take off Unit with Rotary System Unit

Roller Length: 2,400mm; Collapser: Aluminum alloy roller; Light Aluminum Alloy Guiding Roller: Light aluminum alloy guiding roller 1 group;

Haul-off Tower: Column adopts 200 mm*200 mm square tube; Height 12.5 m, 4 floors platform, guardrail height 1.1m

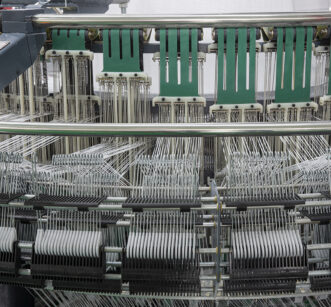

Different Visual

We need Clients to Know about

- before-Sales-Service

Arrangement of Q&C room, spare parts storage, raw material storage, finished products storage and maintenance room ; According to our design drawing and instruction, the buy should prepare all the facilities before the arrival of machinery.

- Commissioning

The machines are supplied in partially assembled condition and require skilled supervision of the seller’s technician(s) for erection & commissioning.

- The Buyer must Know about

Skilled and unskilled labors are to be provided by the buyer; All material handling equipment including suitable for lift truck are to be provided by the buyer.

- Training

For a new customer, the skill operation staff and skill maintenance staff are very important.