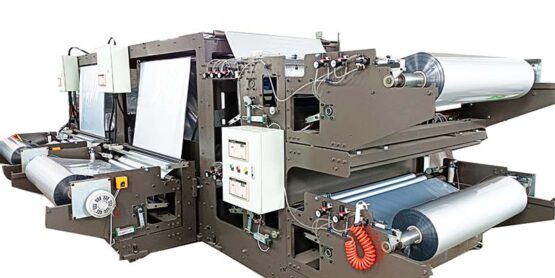

FIBC Big Bag Aluminium Liner Making Machine

Model

LinerSHAPE-ALC

• Liner Width (with Gusset): Max. 1,100 mm

• Liner Length: 1,500-5,000 mm

• 4 Unwinders

• Bag Flange Available

• Multi-layer Co-extrusion Film ( Aluminium Foil Film )

Liner Type:

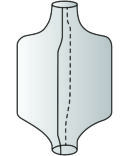

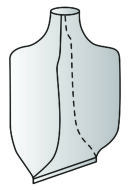

Aluminium Foil Liner: Top and Bottom Bottle Neck / Top Bottle Neck /

Neck / Flat Bottom

Model Different Table

FIBC Aluminum Foil Liner Sealing Machine

1.0 Version

◥ Integrated Structure Design

◥ Sealing Length Mechanical Adjusting

◥ Only Single Valve Attaching

◥ Limited Shape Edge Waste Film Trimming

2.0 Version

◥ Modular Design Structure

◥ Full Servo System Driving

◥ Automatic Adjusting for Different Designing

◥ Arbitrary Shape Waste Film Trimming

Specification | |

|---|---|

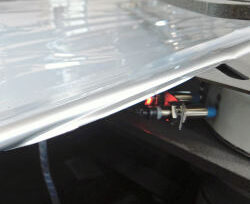

Heat Sealing Width | 7-18mm |

Accuracy | ±2mm/mtr |

Heating Power | 25Kw |

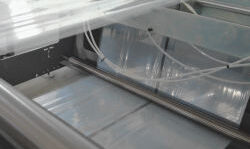

Max. Tubular Film Roll dia | Φ700mm |

Max. Flat Film Roll dia | Φ700mm |

Edge Waste Trimming | Automatic Disc |

Power Supply | 380V, 3 Phase with L3, N, E-50Hz |

Air Pressure | 0.8Mpa |

Air Consumption | 0.2CBM/min |

Units of FIBC Big Bag Aluminium Liner Making Machine

Units of EVOH Liner Making Machine

Details

Aluminum Foil Inliners

Form shaped aluminum in-liners is also known as foil liners, which are made of aluminum-laminated films. Aluminum foil inliners offer superior moisture, oxygen, and UV protection, that protect the quality and integrity of the packed products. Each foil inliner can be produced using various aluminum compounds depending on the specific needs of each application. Degassing valves & valves for gas purging with Nitrogen or Argon.

KEESTAR multi-function liner sealing machine combines comprehensive producing functions of lay-flat inliners and form-fit inliners made of polyethylene film, aluminum foil film and EVOH barrier film.

The film shapes consists of tubular non-gusseted film, tubular gusseted film and flat films.

Model LinerSHAPE-ALC is a intelligent aluminum in-liner making machine line.

Features of Big Bag Liner Making Machine

◥ Automatic Valve Function as Optional

◥ Adjustable Mold Position Left and Right

◥ Finished Product Conveying by Negative Pressure Conveyor

◥ Independent Servo Motor Drive for Feeding and Welding

◥ Servo Cut to Length System

◥ Static Elimination Function

◥ Circulating Water Cooling

◥ Automatic Stop Function

◥ Customizable System Language

◥ PLC Control

◥ Air Shaft

◥ Magnetic Powder Brake Unwinding

◥ Tension Control System

◥ Photoelectric Deviation Correction System

◥ Frequency

◥ Tube Liner and Flat Liner as Optional

◥ Controllable Welding Temperature and Welding Time

◥ Automatic Feeding, Automatic Welding, Automatic Waste Removal, Automatic Punching, Automatic Cold Cutting of Finished Products

Model LinerSHAPE-ALC – FIBC Big Bag Aluminium Liner Making Machine

High-quality Lightweight Tapes

High-tenacity Tapes

Customized Execution

Modular Design