FIBC Big Bag Fabric Cutting Machine

BigbagCUT

Model

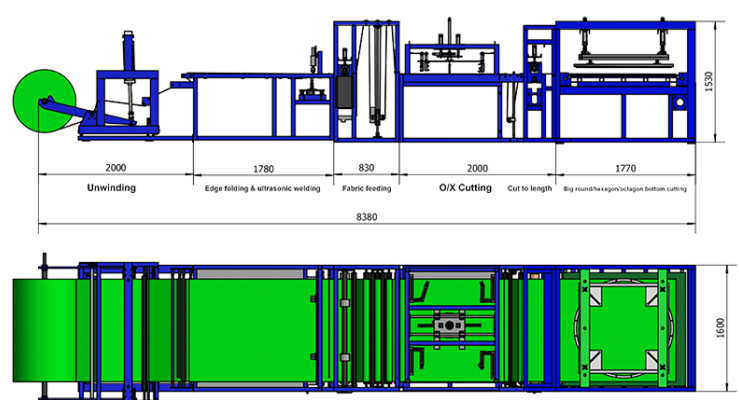

Considering the composition of the container bag body (the maximum width of the tubular fabric and flat fabric for ), we designed two width series, 2250 and 1400.

Our Fabric Cutting machines are available under three machine models: SimpleCUT, BigBagCUT and StarbaseCUT.

The Model BigBagCUT(Big Bag Cutting Machine) is flexibility and comprehensiveness, which bench-type structure has ample space, allowing for modular addition and reduction of workstations.

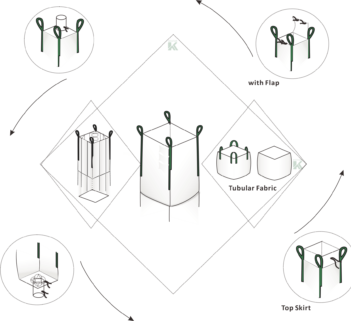

- It can be adapted to a variety of opening molds according to customer needs to meet the diverse bag-type processes in actual production and improve work efficiency.

Advanced new cutting system, output could be reach 30 pcs/min.

● Machine 1,400 for Flat Fabric

● Machine 2,250 for Tubular Fabric

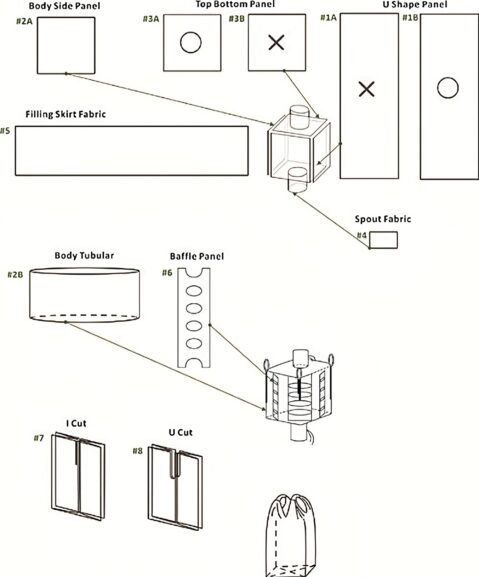

#1A/1B U Shape Panel (O and X holing)

#2A Body Side Panel

#2B Body Tubular

#3A Top Panel (O holing cut)

#3B Bottom Panel (O and X holing)

#4 Spout Fabric

#5 Filling Skirt Fabric

#6 Baffle Panel (Baffle Holing), Option

#7 Body Tubular, One- loop Big Bags

(Longitudinal I Cut), Option

#8 Body Gusseted Tubular, Two-loop Big Bags

(Longitudinal U Cut), Option

Include

Features of Big Bag Fabric Cutting Machine

Model Different Table

BigbagCUT-1400

BigbagCUT-2250

Models | BigbagCUT-1400 | BigbagCUT-2250 |

|---|---|---|

Max.Cutting Width | 1,400mm | 2,250mm |

Rated Power | 8kW | 11kW |

Fabric Feeding Speed | 60-80 m/min, Adjustable | 60-80m/min, Adjustable |

Cutting Length | 300-9,999mm | 300-9,999mm |

Length Accuracy | ±5mm | ±5mm |

O/X Holing Cutter Size | 200-590mm | 200-590mm |

Edge Hemmer | with Ultrasonic Welder, Option | with Ultrasonic Welder, Option |

Fabric | Flat, Gusseted | Flat, Tubular, Gusseted |

Mouth Opener | – | – |

Fabric Roll Diameter | Max. 1,200mm | Max. 1,200mm |

Option List

– Big Bag Fabric Cutting Machine

Model BigbagCUT – FIBC Big Bag Fabric Cutting Machine

Vision Inspection Table

Fabric Burn-proof Cutting

Energy Efficiency Design