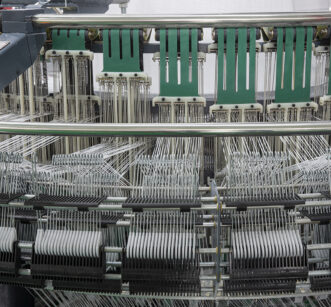

FIBC Big Bag Printing Press Machine

Model

BigbagPRINT

The FIBC Printing Machine is a type of letterpress printing machine that performs chromatic printing on the tubular or flat fabrics, users can choose single-sided or double-sided printing.

Taking into account the actual production needs of jumbo bags (material inlet size, printing range, number of colors, etc.), our Printing Press Machine are classified under two series, BigbagPRINT1500 and BigbagPRINT2000.

- As a durable equipment, the flexographic printing machine achieves stable operating efficiency through high-quality machine materials, reasonable specifications and configurations, thereby extending the service life of the machine, reducing replacement cycles, and ensuring the overall practicality and economy of the Printing Press Machine.

The fabrics that can be printed are flat, tubular, gusseted tubular pieces.

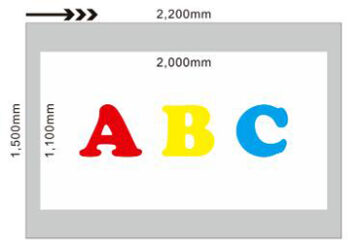

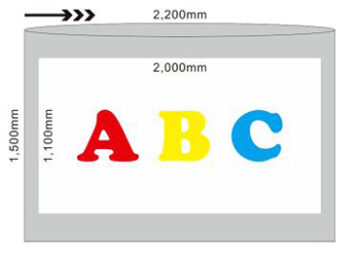

Two different table: 1,500mm & 2,000mm.

Model Different Table

Model

BigbagPRINT-1,500

BigbagPRINT-2,000

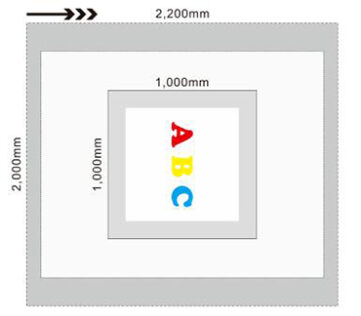

BigbagPRINT-1500 Could Print

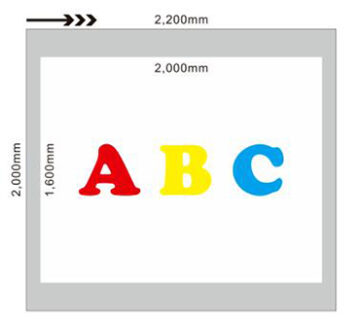

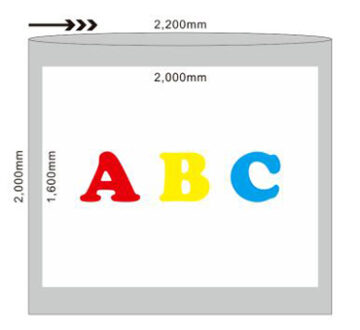

BigbagPRINT-2000 Could Print

Include

Option List – Bulk Bag Printing Machine

Features of Bulk Bag Printing Machine

Specification | |

|---|---|

Fabric | flat, tubular, gusseted tubular pieces |

Output | 2,000 pcs/h, 1mt length fabric |

Printing Method | single side, separate color flexographic press printing |

Printing Plate | photo-polymer, min. 5mm / max. 8mm |

Ink Feed | circulating pump |

Ink Discharge | valve |

Color Register Adjust | non-stop 360° CW or CCW printing roller rotating adjust |

Printing Roller Transmission | synchronization cam |

Water Pressure | 2 Operators, 1 feeding, 1 inspecting & stacking |

Rated Power | 2-Color: 3kW 3-Color: 4kW 4-Color: 5.5kW 5-Color: 7.5kW 6-Color: 10kW |

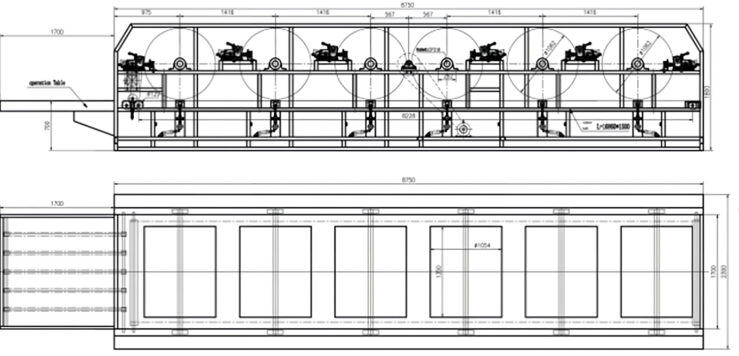

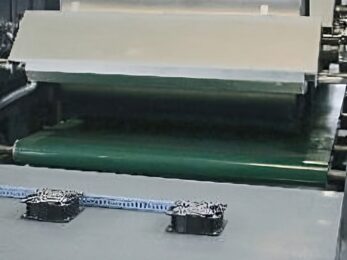

Units of BigbagPRINT

Non-Standard Engineering

We provide a non-standard engineering according to customer’s demand

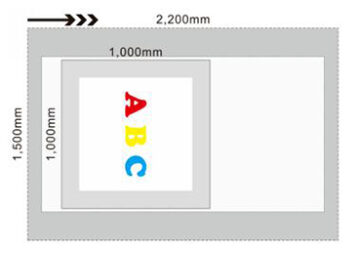

Non-standard BigbagPRINT-1500 Big Bag Printing Press Machine

eg. We could design non-standard BigbagPRINT-1500 by enlarge the diameter of the printing rollers and shorten the width of the printing rollers, thus the new machine could printing on narrow width and longer fabric, starbase or 1-loop / 2-loops style of FIBC container bags are matched.

Non-standard BigbagPRINT-2000 Big Bag Printing Press Machine

eg.1 Enlarge diameter of the printing rollers, longer fabric is available.

eg.2 Reduce diameter of the printing rollers, more output is available.

Model BigbagPRINT – FIBC Big Bag Printing Press Machine

High-performance

Cost-effective

Energy Efficiency Design