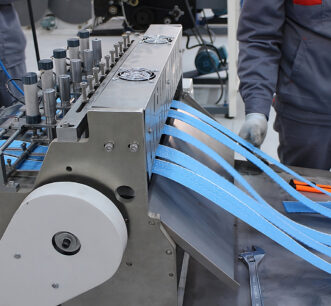

FIBC Big Bag Top Lift Rig

Model

TopLIFT

Our FIBC Big Bag Top Lift Rig, combined with a servo motor, can control the loading speed and pressure holding time.

- The Jumbo Bag Test Rig can observe the stress status of the slings through four sensors, and ensures that the sample slings are evenly stressed in a horizontal position.

- The FIBC Bulk Bag Top Lift Testing Machine can also automatically count and calculate test data and results, and finally output test curves and test reports.

Only the authenticity and accuracy of the data can ensure the reliability of the experimental results.

Our Top Lift Test strictly adheres to this principle and will not let you down.

▪ Quick Filling, 1m³ Material approximately 3 min

▪ Elevator for Transporting the Granulate to the upper Silo

Features of Big Bag Top Lift Test Rig

◥ Tensile Load 1 and 2 Point FIBCs(max.): 150 kN (15.3 T)

◥ Pressure Load 4 Point FIBCs(max.): 200 kN (20.4 T)

◥ Test Force Resolution: 1/±300,000

◥ Advantage Testing Software

◥ Computer+Printer

◥ Remote Controller

◥ Relative Error of Indicating Value: 1%-100% ≤±1%

◥ Repeatability Relative Error: ≤±1%

◥ Rate of Loading: 1.0 kN/s – 10.0 kN/s ± 5%

◥ Loading Type: Servo Automatic Controlling

◥ Bag Type: 4, 2, 1 Loop FIBC Big Bag

◥ Piston Stroke: 0-800 mm, Customized

Model TopLIFT300 – FIBC Big Bag Top Lift Rig

Strong Stability

Energy Efficiency Design

Easy to Control

Automatic Running Cyclic Loading

Set of Load Plates for Different Sizes of FIBCs

Individual Reading for Each of the 4 Load Points