Monofilament Extrusion Line

Model

Mono-80/-90

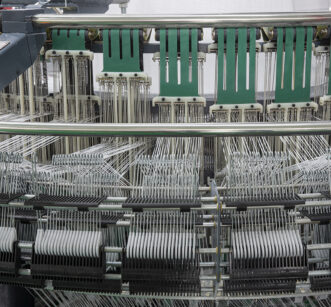

Monofilament Stretching Line is mainly used as a specialized unit for producing high-strength PP and HDPE round wire (hard wire) for a wide range of applications.

Its working principle is similar to Tape Stretching Line.

- Our Monofilament Stretching Lines comes in two series, MONO-80 and MONO-90, based on the diameter of the extruder screw (material rod).

- The machine mainly has two stretching modes, which can be selected according to the customer’s wishes.

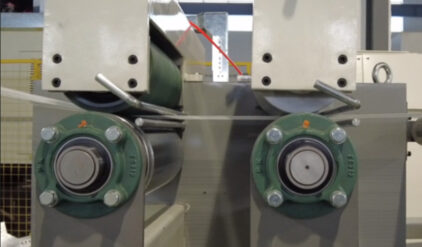

The Monofilament Extrusion Line can be uniformly adjusted for speed under a complete control system, achieving high yield and energy-saving effects.

Features Monofilament Stretching Line

◥ Granulate Mixer

◥ Hopper with Hopper Loader

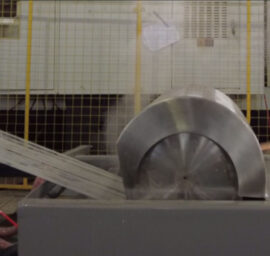

◥ Melt Gear Pump

◥ Continuous Screen Changer

◥ Online Gauging System

◥ Energy Efficient Water or Oven

Units of Monofilament Extrusion ( Stretching ) Line

Models | Mono-80 | Mono-90 |

|---|---|---|

Screw Dia. | ∅80mm | ∅90mm |

Max Extrusion Output | 155kg/hr | 210kg/hr |

Output | 140kg/hr | 180kg/hr |

Max Screw Revolution | 150m/min | |

Max Stretching Linear Working Speed ( Oven ) | 130m/min | |

Max Stretching Linear Working Speed ( Hot Water Tank ) | 120m/min |