Starbase FIBC Big Bag Cutting Machine

Model

StarbaseCUT

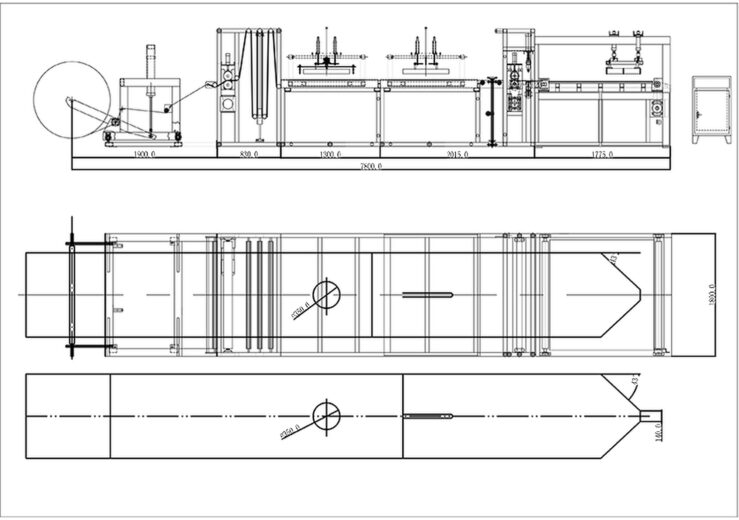

Considering the composition of the container bag body (the maximum width of the tubular fabric and flat fabric for ), we designed two width series, 2250 and 1400.

Our Fabric Cutting machines are available under three machine models: SimpleCUT, BigBagCUT and StarbaseCUT.

The Model StarbaseCUT highlights subdivision and adaptability in design.

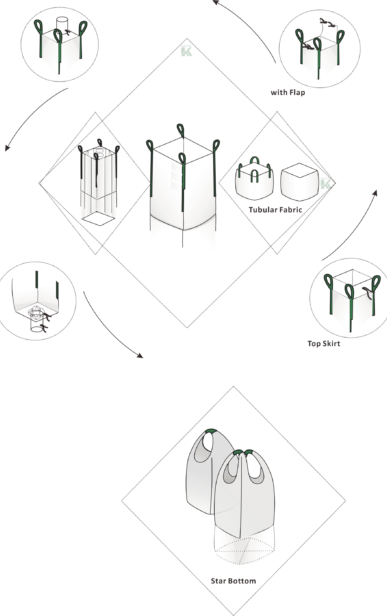

- This Fabric Cutting Machine is mainly designed for a special type of FIBC big bags, that is, a super sack with a bottom composed of four flat-bottomed tapered pieces, usually known as “Starbase“.

- The bag body of Starbase is also processed by the hot cutting system at a special angle, and this station is set after the cutting to length (transverse cutter).

Advanced new cutting system, output could be reach 15-20 pcs/min.

● Machine 1,400 for Flat Fabric

● Machine 2,250 for Tubular Fabric

StarbaseCUT is a special cutting unit design for cutting star bottom gusseted tubular fabric with a V shape cutter.

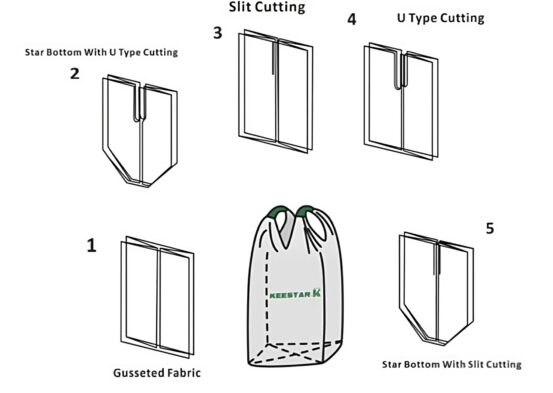

1 Gusseted Fabric

2 Star Bottom With U Type Cutting

3 Slit Cutting

4 U Type Cutting

5 Star Bottom with Slit Cutting

It is a component unit of a complete starbase fabric cutting machine basing on the standard cutting machine BigbagCUT, could not use separately.

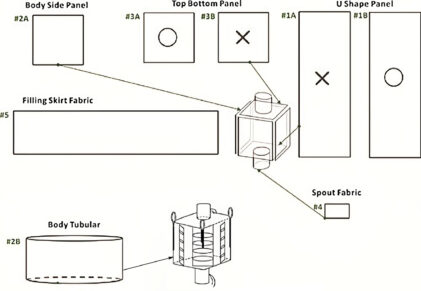

#1A/B U Shape Panel (O and X Holing)

#2A Body Side Panel

#2B Body Tubular(2200 Model Only)

#3A Top Panel (O Holing Cut)

#3B Bottom Panel (O and X Holing)

#4 Spout Fabric

#5 Filling Skirt Fabric

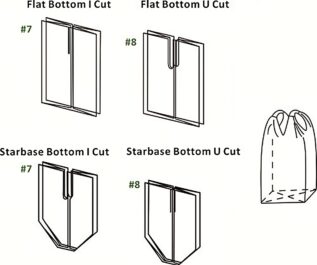

#7 One- loop Big Bag

Flat Bottom I Cut ,Starbase Bottom I Cut

#8 Two-loop Big Bag

Flat Bottom U Cut, Starbase Bottom U Cut

Include

Features of Star Bottom Big Bag Cutting Machine

Model Different Table

StarbaseCUT-1400

StarbaseCUT-2250

Specification | |

|---|---|

Max. V Cutting Width | 1,100mm |

Max. Length Cutting Width | 1,400mm |

V Cut Output | Appr. 8-10 pcs/min |

Fabric | Flat, Tubular, Gusseted |

Cutting Types | Length, V, O, X, I, U |

Option List

– Star Bottom Big Bag Cutting Machine

Model StarbaseCUT – Starbase FIBC Big Bag Cutting Machine

Vision Inspection Table

Fabric Burn-proof Cutting

Energy Efficiency Design