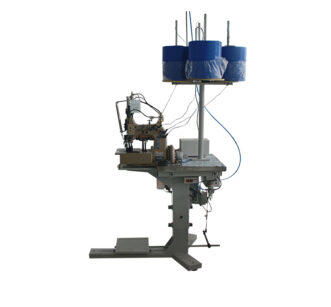

Automatic Big Bag Spout Tube Sewing Machine Unit

Model

SpoutMAKE

The sewing of FIBC container bag spout fabric is a process with relatively intensive manual investment, which is simple and the specifications are uniform.

It is one of the most ideal sewing processes to use automatic equipment to replace manual labor.

The Spout Tube Sewing Unit can realize the automatic production of spout fabric through automatic processing of roll materials, complete the cutting and closing operation in one machine, save the cutting and sewing process.

- The output can reach 960-1,320 pieces/hour.

The Automatic Big Bag Spout Tube Sewing Unit adopts ultrasonic welding of sewing thread chain to prevent it from falling apart, and the spout tube length is adjustable.

Chain stitch sewing machine sewing with automatic thread chain cutting.

▪ Model SpoutMAKE-L

Spout Tube with Top Folding

▪ Model SpoutMAKE-T

Spout Tube without Top Folding

Details

Model SpoutMAKE one step solution design for FIBC big bag filling and discharging spout tube sewing, improves production efficiency, reduces labour costs. One line combines all production processes in spout tube sewing.

▪ Type SpoutMAKE-L

√ Fabric: Flat Fabric Roll

√ Spout Tube Top Folding with Ultrasonic Welding

√ Skirt Fabric as Non-standard Type

√ Tube Width: 500-1,000 mm

√ Tube Length: 500-1,100 mm

▪ Type SpoutMAKE-T

√ Fabric: Tubular Fabric Roll, Flat Fabric Roll

√ Spout Tube Top without Folding

√ Tube Width: 500-900 mm

√ Tube Length: 500-800 mm

Features of Automatic Tonne Bag Spout Tube Sewing Unit

◥ Tying Belts Ends Fixing to Spout Fabric by Ultrasonic Welding

◥ Spout Fabric Feeding with Single/Double Edge Folding

◥ Chain Stitch Sewing Machine Sewing with Automatic Thread

Chain Cutting

◥ Ultrasonic Thread Chain Releasing-proof Treating

◥ Tying Belt Height Adjustable ( ±125 mm )

◥ Tying Belt Length 500-900 mm ( Half Folded )

Specification | |

|---|---|

Edge Folding Width | 18-22mm |

Thread Tail Length After Thread Cutting | 10-20mm |

Fabric Width | 500-1,000mm(SpoutMAKE-L); 500-900mm(SpoutMAKE-T) |

Fabric Length | 500-1,100mm(Half Folded)(SpoutMAKE-L); 500-800mm(Half Folded)(SpoutMAKE-T) |

Fabric Weight | 50-160g/m2 |

Max. Quantity of Sewing Layers Fabric

(Coated) 50-160 g/m2 | 4 |

Max. Quantity of Sewing Layers Fabric

(Non-Coated) 50-100 g/m2 | 8 |

Output | Max. Output 16pcs/min (SpoutMAKE-L); Max. Output 22pcs/min(SpoutMAKE-T) Based on Skilled Chinese Workers 7,680 pcs/8 Hours and 10,560 pcs/8 Hours by Skilled Chinese Workers |

Finished Spout Stacking Quantity | 1-50pc |

Distance Between Sewing to Finished Edge | 16-18mm |

Model SpoutMAKE – Automatic Big Bag Spout Tube Sewing Machine Unit

Spout Tube Sewing

Strong Stability

Energy Efficiency Design