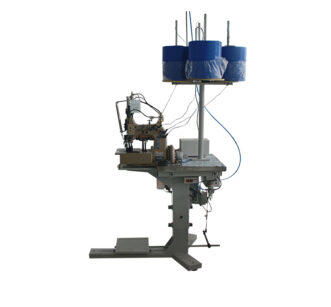

Big Bag Overedging Sewing Machine

Model

81500BA1HL

Our Big Bag Overedge Stitch Sewing Machine is mainly used to sew various pieces of container bag body, mainly including,

- container bag side seam on fabric and loop with filler cord,

- bulk bag top and bottom panel seam with filler cord,

- jumbo bag very heavy duty corner seam etc.

The FIBC Sewing Machine adopts 1 needle, 2 thread overedge stitch(502), which can be used to sew the elastic parts of the container bag.

Equipped with both plain and alternating upper fabric feeding system, it’s especially suitable for side seams on very heavy weight fabric of FIBC, and with top and bottom filler cord guides for sealing the needle punctures.

The sewing capacity can reach a thickness of Max. 19 mm, which meets the sewing process requirements of all jumbo bags.

Details

◥Model 81500BA1HL is a overedge sewing machine for big

bag seaming, same with model 81300A1HL expect with only

1 needle, 2 threads, overedge seams.

◥Basic Model 81500A, without Pneumatic Presser Foot Lifter

and any Cutter

◥Need Pneumatic Presser Foot Lifter, without Hot Cutter, Model

81500BA2

◥Need Pneumatic Presser Foot Lifter+Left Side Pneumatic

Operated Hot Cutter, Model 81500BA1HL

Model | 81500BA1HL

| GN20-2

|

|---|---|---|

Stitching Type | 502 | 502 |

Overedge Width | 10mm | 15mm |

Sewing Capacity | up to 19mm | up to 12mm |

Standard Needle | UY9853 430# | GN20 300# |

Stitch Range | 6 to 13mm (Standard Setting 10mm) | 6 to 13mm (Standard Setting 10mm) |

Speed | up to 1,400rpm | up to 1,400rpm |

Filler Cord | Unavailable | Unavailable |

Model GN20-2A is a economic overedge sewing machine for big bag seaming, with 1 needle, 2 threads, overedge seams.

Model 81500BA1HL- Big Bag Overedging Sewing Machine

Pneumatic Operated Hot Thread & Filler Cord Cutter

Overedging Sewing Machine

Energy Saving, Fast Speed

Extra Heavy Duty Sewing Capacity

Servo Motor Driven